Description

Material

Carbide,ASP23,Vanadis,CPMRTXM4,SKD11,SKD61,HSS,A2,M2,D2,SUJ2,S45C,ect

Standard

Dayton,Lane,DIN,ISO,MISUMI,EDM,FIBRO,MOELLER,HASCO,ect

Size

Depend on your drawings or products standard

Place of origin

Dongguan, Guangdong, China

Heat treatment

Available

Surface Work

TiCN, TiN, Aitain, Ticrn, nitriding , Black oxygened, Black coating etc available

Tolerance

+ - 0.002mm

Polishness

Close to Ra0.2

Hardness

Depends on material(HRC60~94)

Delivery time

3-5 Working days, depends on the quantity the order. Express by DHL, UPS, FEDEX, TNT or Ocean Shipping etc.

Main Products

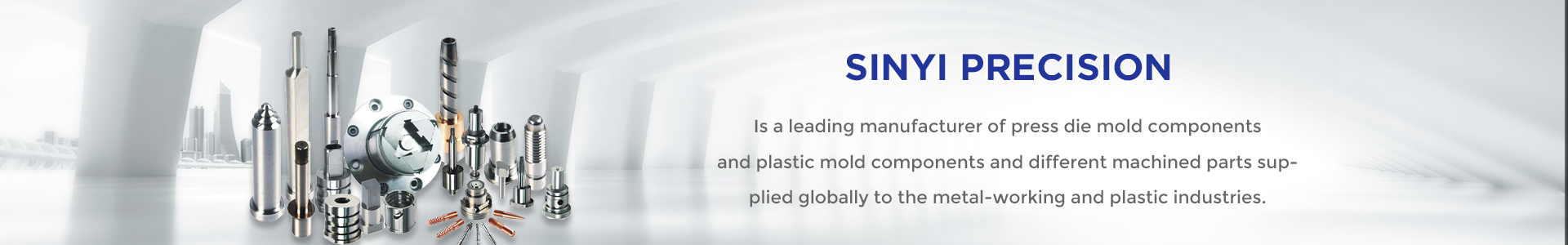

Guide elements, punch pin, die button, ejector pin and sleeve, oilless bush, etc.

Can be customized according to the specifications, production and processing,

Specializing in the production of high precision pen model core, inserts, inserts, cavity, screw teeth inserts, front and rear die inserts, tooth rod, push plate sleeve, photoelectric tooth shaft, fixture, bump die, punches, movable core components, ejector sleeves, ejector pins, support pins, pull rod,sprue gate and other products processing custom.

Materials Tungsten Carbide, Stainless Steel, Aluminum Alloy, Brass Alloy, Plastic, Carbon Steel, Die Steel, Spring Steel, etc.

Products Stamping, Punches and Dies, Tungsten Carbide Parts, Ejector Pins/Leader, Special Toolings, Injection Mould Parts, CAM Components, Mold Springs, Mold Base, Bolts, Press Fittings, Guiding Components, Thick/Thin Turrent Tooling, Turmpf Tooling, MUrata Wiedemann Tooling, Salvagnini Tooling, High Performance Coating, Multi-Tools, Turning and Milling Parts, CNC Machinery Parts, etc.

Precison Parts Ejector Sleeves, Pin-point Gate Bushing, Leader/Guide Pins, Leader/Guide/Sprue Bushings, Ball Retainers, Slide Locks, Taper Pin Sets, Taper Block Sets, Air Poppet Valves, Air Jet Valves, Date Marked Pins, Locating Rings, Multi-Shape Punches and Dies,

Standard Standard Hardware/ Plastic Parts as per MISUMI, DME, HASCO, FIBRO, CUMSA, STRACK, DAYTON

NON-Standard parts can be designed or made customized

Tolerance ±0.001mm

Coating TiN/ TiCN/ AlTiN/ TiAlN/ CrN/ DLC/ AlCrTIN/ TiCrN/ WC/C/ CrAlN/ ZrN/ SiALTi-XN...

Lead Time Sampling: 7-10 workdays

Normal making: 10-12 workdays

Complex design/making: 15-20 workdays

Order Process Customer inquiries → Provide Spec./CAD/3D drawing → Engineer check and quote → Offer PI → Customer Send PO → 50% advanced payment(100% for First time cooperation) → Factory production process → QC passed √ → Packing and deliver at the first time → Fly to customers' hands soon!

Factory Working Time Monday to Saturday

Production Process Turning on Lathe → Milling → Heat Treatment → Coreless Grinding → Turning and Milling → Diameter Grinding → Flat Grinding → Wire cutting → EDM → Surface Treatment → Inspection → Packing and Shipping (Just for your reference)

After-sell Service Contact SINYI if have any question after receiving the samples and products, our team will try best to offer you the best quality!